The r value of wet spray and dense pack cellulose insulation depends slightly on its installed density and the exact type of cellulose used but commonly ranges between 3 6 and 3 8 per inch 1 as measured by the standard astm c518 test.

Wet spray cellulose insulation r value.

The r value per inch decreases slightly as density is increased from 3 0 to 4 0 lbs ft3.

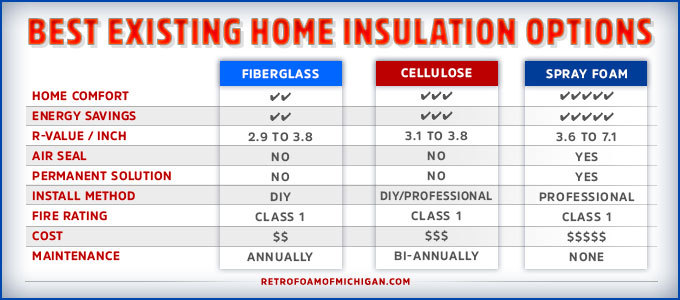

In comparison an inch of blown fiberglass insulation has an r value of 3 1 3 4 and an inch of blown cellulose in an attic has an r value of 3 2 3 7.

Loose fill cellulose is relatively inexpensive yet still has an r value of about 3 5 per inch of thickness compared to fiberglass r value between r3 to r4 per inch.

The r value per inch decreases slightly as density is increased from 3 0 to 4 0 lbs ft3.

Drying time for wet spray.

Nu wool premium cellulose insulation is a superior product designed for use in walls attics and floors of new and existing residential and commercial structures.

Cellulose is among the oldest types of building insulation material.

Modern cellulose insulation made with recycled newspaper using grinding and dust removing machines.

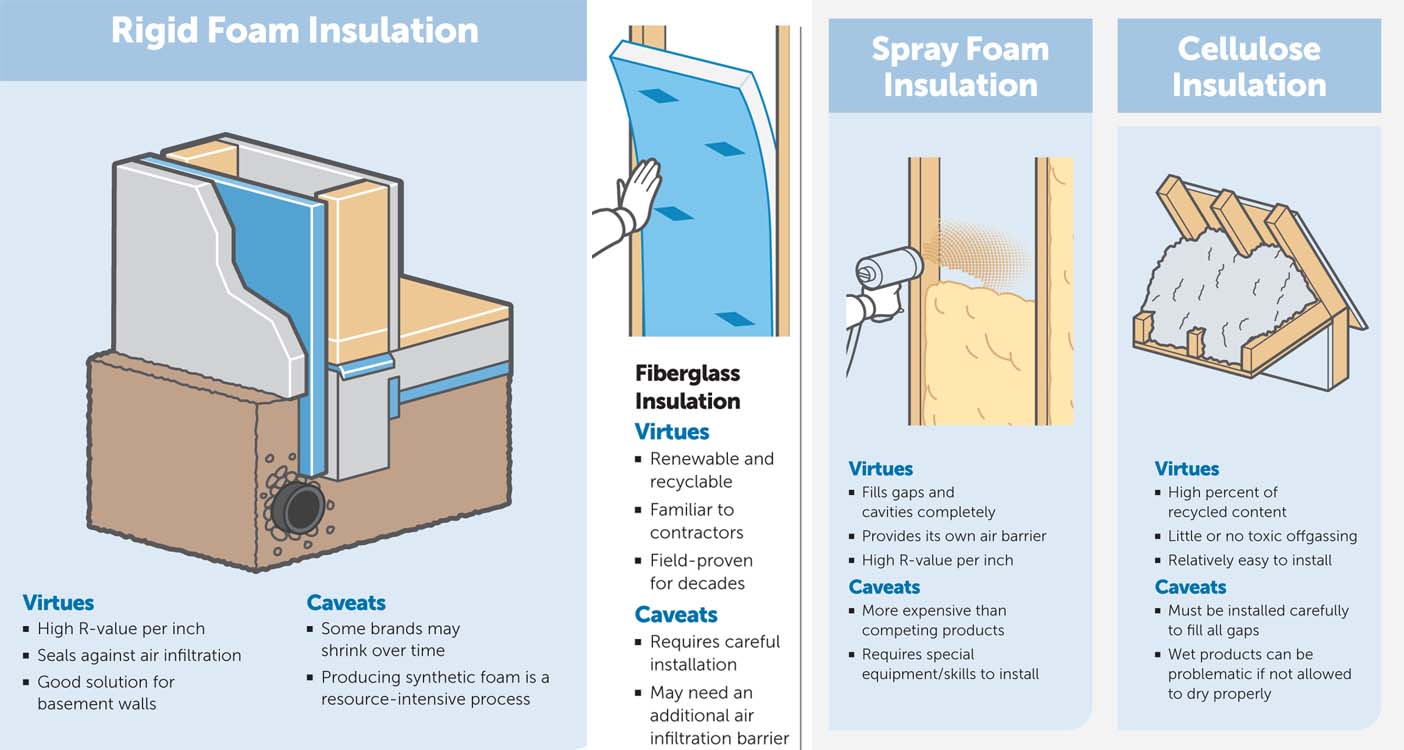

Wet spray is used for better sealing but takes a very long time to dry.

Citation needed many types of cellulosic materials have been used including newspaper cardboard cotton straw sawdust hemp and corncob monticello was insulated with a form of cellulose.

Cellulose insulation weighs more than fiberglass for the same r value.

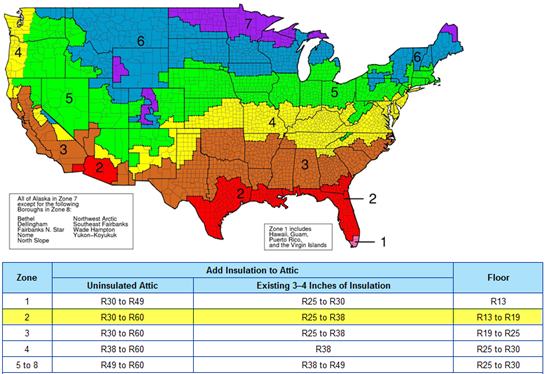

Along with knowing the r value of a particular insulation it is also important to calculate the r value of a total system.

It can be blown in by using air or spread by hand.

As a benchmark one inch of solid wood has an r value of 1.

Loose fill cellulose insulation can settle around and conform to most of the obstructions found in walls and attics.

This versatile formula has a dry adhesive which is activated with a fine water mist during installation that is designed to enhance performance.

History of cellulose insulation.

When walls are already finished injecting loose fill cellulose insulation is one of the few ways of adding.

Pit falls of wet blown cellulose.

Removal of cellulose insulation is costly.

Related to this we have seen some cellulose contactors still using small cans of spray polyurethane insulation to air seal new homes.

Cellulose installation can be done in either a dry installation method or a wet method.

Unlike fiberglass insulation which improves with the increase of density cellulose insulation offers the same protective values across the board regardless of material density.

Spray applied sanctuary spray applied insulation products are optimized for wall spray or open attic installations.

The study also concluded wet blown cellulose is not an effective air barrier.